How to Maintain Your CO₂ Laser Machine for Optimal Performance

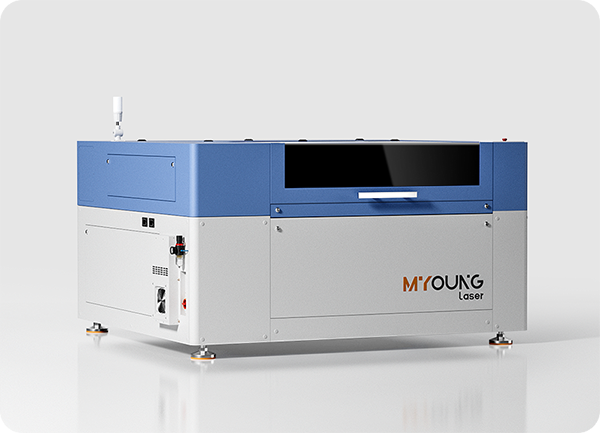

Maintaining a CO₂ laser machine is essential to ensure long-term accuracy, efficiency, and safety. Whether you’re using the machine for acrylic cutting or other materials, consistent care will help avoid costly downtime and maintain production quality. In this article, we’ll walk you through key maintenance practices that will help your MYounglaser system perform at its best.

1. Clean the Optical Components Regularly

Dust, smoke, and residue from acrylic or other materials can build up on the mirrors and lens. Use a proper lens-cleaning solution and lint-free wipes to clean these parts:

- Clean the lens after every few hours of operation.

- Check mirrors weekly for buildup or discoloration.

- Ensure the focus lens is free from scratches or cracks.

Neglecting this can lead to laser beam deflection and power loss.

2. Check and Replace the Laser Tube

The CO₂ laser tube is the heart of the machine. For acrylic laser cutting, it’s important to:

- Monitor laser intensity and stability.

- Replace the tube when the power drops significantly (usually after 2,000–4,000 hours depending on usage and quality).

- Keep the tube area clean and ensure the water cooling system is functioning properly.

With MYounglaser CO₂ laser machines, high-quality laser tubes ensure stable and long-lasting performance.

3. Maintain the Water Cooling System

Acrylic cutting generates heat, which must be managed effectively:

- Use clean, distilled water in your chiller or cooling system.

- Change water every 1–2 weeks.

- Ensure there are no air bubbles in the tube, as they can cause overheating.

MYounglaser machines come equipped with intelligent cooling options to help prevent overheating.

4. Lubricate Guide Rails and Moving Parts

To maintain precision:

- Apply lubricant to linear guides every 1–2 weeks.

- Ensure belts, pulleys, and bearings are properly tensioned.

- Remove any acrylic debris stuck in the rail or gantry system.

Our Dura Series is equipped with linear module guide rails featuring self-cleaning functionality for smoother, quieter motion.

5. Perform Software and Electrical System Checks

- Back up design files and check for firmware updates.

- Inspect wiring, connectors, and switches monthly.

- Ensure the grounding system is intact to avoid static-related issues.

Reliable software and control systems, such as those used in MYounglaser CO₂ machines, enhance safety and performance.

6. Clean the Exhaust and Air Assist System

A clean exhaust fan prevents acrylic fumes from building up:

- Clean ducts and filters every month.

- Ensure airflow is strong to maintain a clean cutting environment.

- Clean or replace the air compressor filter when airflow weakens.

Why Choose MYounglaser for Your Acrylic CO₂ Laser Cutting Needs?

At MYounglaser, we design every machine with precision, efficiency, and durability in mind. Our Dura Series machines come with:

- Japan Shinano motors for high torque and smooth motion

- Self-cleaning linear rails that reduce manual maintenance

- Reliable laser tubes and power supplies from trusted suppliers

- Strict quality controls for every unit shipped

Proper maintenance of your acrylic CO₂ laser cutting machine is not just about keeping it running—it’s about ensuring maximum performance and profit over time. Whether you’re an individual crafter or a production business, investing in regular upkeep is key.

Explore our range of MYounglaser CO₂ laser machines today and get personalized recommendations for your business.

Visit our website or contact our team for more information.

Budget Series

Dura Series

MIX Series