The Future of CO₂ Laser Machines: Trends to Watch in 2025

As we enter 2025, the CO₂ laser machine industry is undergoing rapid transformation driven by advancements in technology, growing demand for customization, and broader industrial adoption. Whether you’re a manufacturer, hobbyist, or a business looking to invest, keeping an eye on upcoming trends is essential. Here’s what to expect in the evolving world of CO₂ laser machines.

1. Smarter CO₂ Laser Machines with AI Integration

Artificial intelligence is beginning to play a significant role in laser technology. In 2025, expect more AI-enhanced CO₂ laser machines that automatically optimize cutting paths, detect anomalies in real-time, and provide predictive maintenance alerts. This reduces downtime and ensures consistent performance.

2. Increased Automation for Industrial Workflows

Modern factories are adopting automated laser cutting systems that integrate with conveyors, robotic arms, and production software. For CO₂ laser machine suppliers like MYounglaser, automation offers the ability to deliver turnkey systems that support 24/7 operations with minimal human intervention.

3. Eco-Friendly Cutting Technologies

With stricter global environmental regulations, energy efficiency and waste reduction are top priorities. 2025 will see a surge in green CO₂ laser solutions, including machines with improved power efficiency, better fume extraction systems, and compatibility with recyclable materials like cast acrylic.

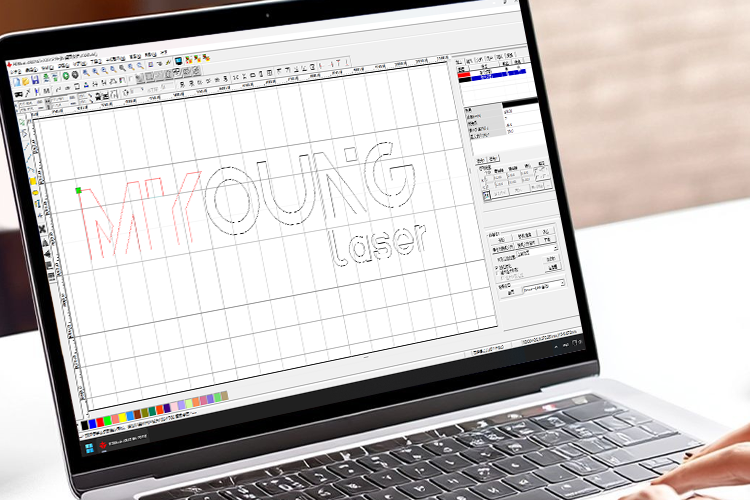

4. Enhanced Precision for Intricate Designs

As the demand for fine-detail cutting grows—especially in the acrylic CO₂ laser cutting machine segment—manufacturers are developing machines with higher resolution optics and advanced motion control systems. These improvements enable intricate engraving and micro-cutting across a variety of materials.

5. Compact Models for Small Businesses and Creators

The rise of makerspaces and small businesses has led to increased demand for compact, affordable CO₂ laser machines. In 2025, expect more plug-and-play models from brands like MYounglaser, offering industrial-grade performance in a tabletop format.

6. Seamless Cloud Connectivity and Remote Monitoring

Wi-Fi-enabled CO₂ laser machines with cloud-based control systems will become standard. Users can upload designs, monitor performance, and run diagnostics from anywhere. This is especially valuable for distributed manufacturing environments and remote workshops.

7. Stronger Market Competition and Customization

With growing global demand, more CO₂ laser machine suppliers are offering customizable features—such as interchangeable lenses, specialized cutting heads, and software add-ons—to tailor machines for specific industries like signage, packaging, or medical devices.

8. Cross-Technology Integration

In 2025, CO₂ laser systems will increasingly be paired with UV printing, CNC routing, or fiber lasers to enable all-in-one processing lines. This offers unmatched flexibility for businesses handling diverse projects.

The CO₂ laser machine industry is evolving quickly, and 2025 will be a landmark year for smarter, more efficient, and more user-friendly equipment. Whether you’re upgrading your current setup or entering the market for the first time, keeping pace with these trends will help you stay competitive.

If you’re looking for cutting-edge solutions, MYounglaser continues to lead as a trusted name among CO₂ laser machine suppliers, offering reliable and innovative acrylic CO₂ laser cutting machines for all levels of users.

Budget Series

Dura Series

MIX Series